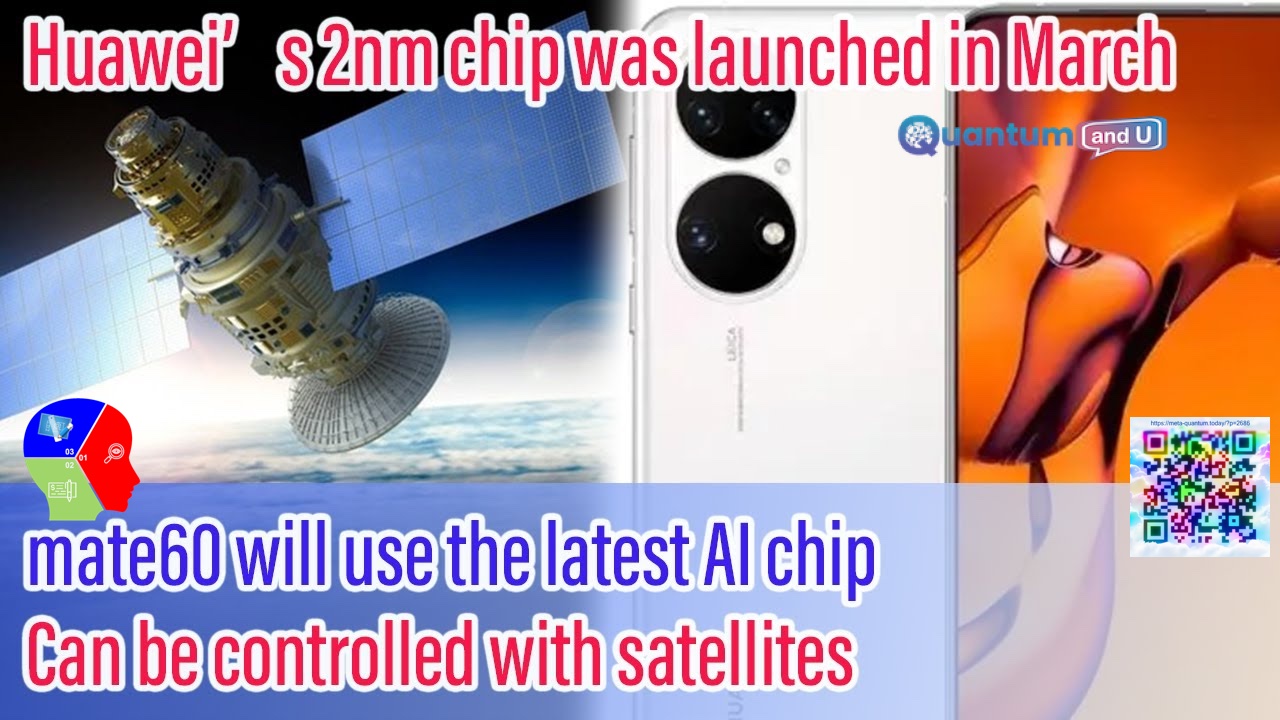

Introduction: The video highlights Huawei’s significant advancements in semiconductor technology, specifically the launch of its groundbreaking 2nm chip in March. This launch marks a new milestone in Huawei’s technological innovation, particularly for the Mate60 series, one of Huawei’s flagship product lines.

The video elaborates on the impressive capabilities of the latest AI chip, showcasing Huawei’s commitment to technological advancement. The chip’s standout feature is its ability to control satellites, demonstrating its immense power and potential for future applications.

SMIC

SMIC, or Semiconductor Manufacturing International Corporation, is the largest contract chip maker in mainland China. They provide a variety of chip manufacturing services, with their most advanced process technology currently at 7nm. However, there are reports that they are on track to achieve mass production of 5nm chips by later in 2024.

Chip production is a complex and fascinating process. Here’s a simplified breakdown of the general steps involved:

- Design: The process begins with the design of the chip. This is done by chip designers using specialized software.

- Fabrication: The design is then transferred to a silicon wafer, which is the base material for the chip. This process involves a series of photolithography steps, where light is used to create patterns on the wafer.

- Etching: The unwanted material is then removed from the wafer using a process called etching.

- Doping: Doping introduces impurities into the silicon to change its electrical properties. This is essential for creating the transistors and other components of the chip.

- Metallization: A layer of metal is deposited on the wafer to create the electrical connections between the transistors.

- Testing and Packaging: The completed chips are then tested to ensure they function properly. Finally, they are packaged to protect them from damage.

SMIC uses a variety of techniques and equipment to carry out these steps. One important piece of equipment is a photolithography machine, which uses light to create patterns on the silicon wafer.

There are two main types of lithography used in chip production: extreme ultraviolet (EUV) lithography and deep ultraviolet (DUV) lithography. EUV lithography is the more advanced technology, but DUV lithography is still widely used.

SMIC has been unable to obtain EUV lithography machines from ASML, the only company that currently manufactures them, due to U.S. restrictions. However, they are reportedly developing their own 5nm process using DUV lithography.

Video about Huawei new chip:

Video Sections:

- Introduction to SMIC and Huawei Partnership:

- SMIC, a prominent semiconductor manufacturer in China, offers Huawei OEM services for 7nm chips.

- Benefits include technological prowess, cost control, and smooth collaboration history.

- Challenges such as complex manufacturing processes and supply chain issues are also addressed.

- Huawei’s Chip Developments and Challenges:

- Huawei’s 7nm chip development success attributed to partnerships with Chinese foundries like SMI.

- The video explores the technological advancements in Huawei’s laptop chips and the potential use of HarmonyOS.

- Emphasis on Huawei’s efforts to secure alternative supply chains amid geopolitical tensions.

- Huawei’s Kirin Chip Series:

- Details on Huawei’s Kirin chip series applications across various products.

- Discussion on Huawei’s self-sufficiency efforts and its impact on the semiconductor industry.

- Comparison with Qualcomm Snapdragon and Apple’s A-series chips, highlighting manufacturing partnerships.

- The Future of Semiconductor Manufacturing:

- Insights into TSMC’s advancements in 3nm chip production and its implications for the industry.

- Analysis of TSMC’s lead over Samsung in technology and production capacity.

- Speculation on Samsung’s challenges in catching up with TSMC by 2030.

- Evaluation of Kirin 9000 Chip:

- Examination of Huawei’s Kirin 9000 chip, focusing on its architecture and performance.

- Comparison with Kirin 9000, emphasizing slight differences in CPU, GPU, and NPU configurations.

- Expectations regarding its integration into Huawei’s upcoming P50 series.

SMIC’s Impact on Southeast Asia and Market Opportunities

SMIC’s presence has a significant impact on Southeast Asia’s tech landscape, creating both challenges and opportunities. Here’s a breakdown:

Impact:

- Cost-effective Chip Production: SMIC offers a more cost-competitive alternative to established chipmakers like TSMC (Taiwan). This could benefit Southeast Asian companies looking to source chips for their electronics manufacturing or local tech startups needing chips for their products.

- Reduced Reliance on Other Regions: Southeast Asian countries can potentially reduce their dependence on chip production giants outside the region. This can offer more control over their supply chains and potentially lead to faster innovation cycles.

- Potential for Tech Hub Growth: SMIC’s presence could encourage the development of a more robust semiconductor ecosystem in Southeast Asia. This could attract further investments in chip design, packaging, and testing facilities, fostering a regional tech hub.

Market Opportunities:

- Chip Design and Packaging: As Southeast Asia looks to leverage SMIC’s production capabilities, there’s a potential rise in demand for chip design and packaging services in the region. Companies specializing in these areas can cater to businesses utilizing SMIC’s manufacturing.

- Testing and Verification: SMIC’s chips might require additional testing and verification due to their potentially less advanced technology compared to some competitors. This creates a market opportunity for companies offering chip testing and verification services in Southeast Asia.

- Partnerships and Joint Ventures: Collaboration between Southeast Asian companies and SMIC for joint ventures or technology transfer could be beneficial. This could lead to knowledge sharing and further development of the regional chip industry.

Challenges:

- Technological Gap: SMIC currently lags behind industry leaders in terms of process technology. This could limit the types of chips they can produce for Southeast Asian companies, potentially hindering the adoption of cutting-edge technologies in the region.

- Geopolitical Tensions: The ongoing trade war between the US and China could impact SMIC’s access to certain materials and technologies. This could lead to supply chain disruptions and affect Southeast Asian companies relying on SMIC.

Conclusion:

Huawei’s journey in semiconductor technology showcases China’s technological capabilities and its strategic partnerships with foundries like TSMC. Despite challenges, Huawei’s progress in chip design and manufacturing emphasizes its resilience. The review emphasizes the importance of Huawei’s Kirin series in the global semiconductor field.

In summary, SMIC’s market presence offers a unique opportunity for Southeast Asia! By leveraging cost advantages and cultivating a strong regional ecosystem, Southeast Asia can establish itself as a significant player in the global semiconductor industry. However, it’s vital to address the technological gap and navigate geopolitical complexities to ensure sustainable growth.

Takeaway Key Points:

- Huawei’s collaboration with Chinese foundries like SMIC boosts its chip development capabilities.

- Huawei’s Kirin chip series demonstrates its commitment to self-sufficiency in semiconductor manufacturing.

- TSMC’s advancements in 3nm chip production signal the future of semiconductor manufacturing.

- Samsung faces challenges in catching up with TSMC’s lead in technology and production capacity.

Related References:

- Huawei’s Semiconductor Ambitions

- TSMC’s Advances in 3nm Chip Production

- Samsung’s Semiconductor Challenges

This comprehensive review provides insights into Huawei’s semiconductor developments, challenges, and future prospects amidst the evolving geopolitical landscape and technological advancements in the industry.